Natural Rubber Process

Other CLIMA Machinery

All the data are base on our 30 natrual rubber processing plant and are only for customers' reference, we can adjust the specification according to your requirements.

|

|

Slab Cutter Machine is primarily designed as an extremely rugged and efficient first stage size reduction machine to reduce the size of large lumps of latex coagulum or agglomerated lower grade into small pieces for mixing or breaking processing. Other, reduce the size before baling for checking the drying quality. |

|

Hammermill Machine is designed for pre-cleaning of dirt as well as initial size reduction of field materials of crumb or pre-coagulated rubber in the lower grade processing line in the natural rubber industry. This machine is recommended to serve as a machine to remove the high dirt content in the raw materials at the beginning stage.

Motor makes hammer high speed rotate through belt driving, then the rubber chip entering between hammer and feed roller would be hammered repeatedly, break into granule, and discharge from semi-circle screen mash hole.

|

|

|

|

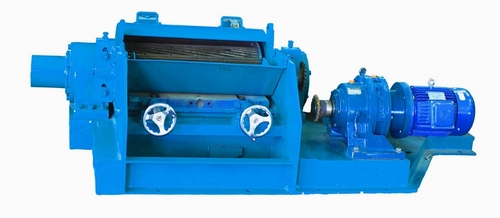

Prebreaker Machine is generally knows as the pre-cleaner. This machine has been designed for the use as an intermittent size reduction machine in the lower grade processing line of natural rubber industry. It is also capable to serve as a machine to remove the high dirt content in the materials.

|

|

Rubber granulating machine is cut into granule through the relative tangential motion between cutting roller and fixed cutter. Alloy-cast-steel with corrosin-resistant and anti-abrasive features is selected for principal roller. Granulating rubber chip with some moisture and thickness, can process more than 5000t rubber stuff, with rather low working noise, well dewater effectiveness and high efficiency.

|

|

|

|

Creper Machine with special groovings is designed for excellent efficiency for cleaning and crepe thickness reduction of rubber blocks and rubber granule at the intermediate second stages and final stage of the cleaning process. Its special designed Rollers and methodology groovings can perform the intermediate cleaning process and simultaneously reducing the size of the thick blankets of crumb rubber crepes enhancing a better constant drying efficiency after the trolley dryer.

|

|

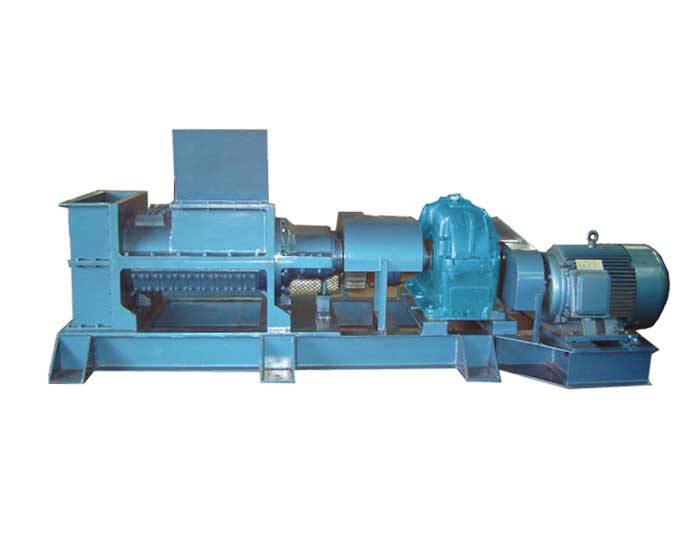

Crusher/Extruder machine is used in breaking and washing natural slab rubber. The machine has been proven to be used very successfully in the second stage size reduction of crumb rubber & pre-cleaning machine.It can replace the Hammermill,Extruder and washer.Slab rubber would be extruded and broken by left and right spiral screw rods with reverse revolution, When rubber is extruded to exit, the rotary scraper would cut the slab rubber into broken bits.

|

|

|

|

Rubber Baling Press Machine is specially designed Press in which to meet extremely rugged performance in Rubber Industry, for high efficiency and effortless automatic baling of crumb rubber into bales form. This machine has been substantially proven that ensures the bale production in the economical ways and stand up to the most baling requirements.

|

|

Hot Air Furnace RFL Series upright cylindrical indirect heating furnace is a high-efficiency new type equipment developed by our factory combining with several years`experience in heat source. The furnace integrates combustion and heat exchange in the one body.

|

|

|